Description

John Deere TM1700 Greens Mower 2500B 2500E Technical Service Manual

108mb, 814 pages.

The original technical manual from Deere. Bookmarked with sections, chapters and sub chapters.

This manual is printable for working on your greens mower on the course or in the workshop without the need of a computer. Just print the pages you need for the day. Easy.

Main Chapters include –

Safety

Specifications and Information

Gas Engine

Diesel Engine

Electrical

Power Train

Hydraulics

Steering

Brakes

Attachments

Misc Info

Main Chapters and Sub Chapters –

Introduction

Manual Description

Safety

Recognize Safety Information

Understand Signal Words

Replace Safety Signs

Handle Fluids Safely – Avoid Fires

Use Care In Handling and Servicing Batteries

Prevent Battery Explosions

Prevent Acid Burns

Wear Protective Clothing

Use Care Around High-Pressure Fluid Lines

Service Machines Safely

Use Proper Tools

Park Machine Safely

Support Machine Properly and Use Proper Lifting Equipment

Work In Clean Area

Using High Pressure Washers

Illuminate Work Area Safely

Work In Ventilated Area

Warning: California Proposition 65 Warning

Remove Paint Before Welding or Heating

Avoid Harmful Asbestos Dust

Service Tires Safely

Avoid Injury From Rotating Blades, Augers and PTO Shafts

Service Cooling System Safely

Handle Chemical Products Safely

Dispose Of Waste Properly

Live With Safety

Specifications and Information

Table of Contents

Specifications

Specifications:General Vehicle

Repair Information

Metric Fastener Torque Values

Metric Fastener Torque Values – Grade 7

Inch Fastener Torque Values

O-Ring Seal Service Recommendations;Seal, O-Ring Service Recommendations

Fuel

Using Proper Fuel

Oils & Lubricants

Engine Oil

Hydrostatic Transmission and Hydraulic Oil

Biodegradable Oil

Converting From HY-GARD to BIO HY-GARD

Grease

Alternative Lubricants

Synthetic Lubricants

Lubricant Storage

Mixing of Lubricants

Oil Filters

Coolant Specifications

Engine Coolant

Engine Coolant Drain Interval

Identification Numbers

Identification Number Locations

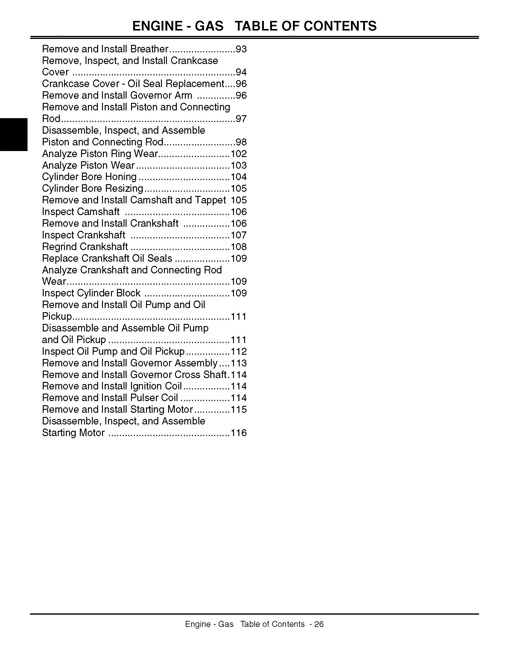

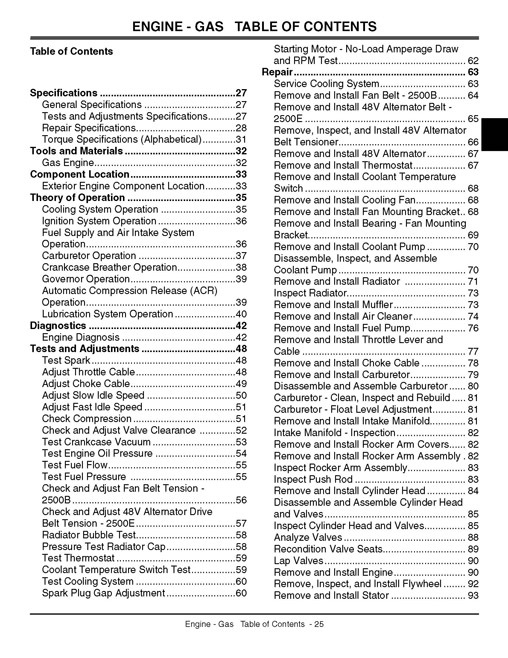

Engine – Gas

Table of Contents

Specifications

Specifications:General

Specifications:Tests and Adjustments

Specifications:Repair

Specifications:Torque

Tools and Materials

Tools and Materials:Gas Engine;Gas Engine:Tools and Materials

Component Location

Component Location:Gas Engine;Gas Engine:Component Location

Theory of Operation

Cooling System Operation

Ignition System Operation

Fuel Supply and Air Intake System Operation

Carburetor Operation

Theory of Operation:Crankcase Breather;Crankcase Breather:Theory of Operation

Theory of Operation:Governor;Governor:Theory of Operation

Automatic Compression Release (ACR) Operation

Lubrication System Operation

Gas Engine:Troubleshooting;Troubleshooting:Gas Engine

Engine Diagnosis

Tests and Adjustments

Test Spark

Adjust Throttle Cable

Adjust Choke Cable

Adjust Slow Idle Speed

Adjust Fast Idle Speed

Check Compression

Check and Adjust Valve Clearance

Test Crankcase Vacuum

Test Engine Oil Pressure

Test Fuel Flow

Test Fuel Pressure

Check and Adjust Fan Belt Tension – 2500B

Check and Adjust 48V Alternator Drive Belt Tension – 2500E

Tests and Adjustments:Radiator Bubble Test;Radiator:Tests and Adjustments:Bubble Test

Pressure Test Radiator Cap

Test Thermostat

Coolant Temperature Switch Test

Test Cooling System

Spark Plug Gap Adjustment

Starting Motor – No-Load Amperage Draw and RPM Test

Repair

Service Cooling System

Remove and Install Fan Belt – 2500B

Remove and Install 48V Alternator Belt – 2500E

Remove, Inspect, and Install 48V Alternator Belt Tensioner

Remove and Install 48V Alternator

Remove and Install Thermostat

Remove and Install Coolant Temperature Switch

Remove and Install Cooling Fan

Remove and Install Fan Mounting Bracket

Remove and Install Bearing – Fan Mounting Bracket

Remove and Install Coolant Pump

Disassemble, Inspect, and Assemble Coolant Pump

Remove and Install Radiator

Inspect Radiator

Remove and Install Muffler

Remove and Install Air Cleaner

Remove and Install Fuel Pump

Remove and Install Throttle Lever and Cable

Remove and Install Choke Cable

Remove and Install Carburetor

Disassemble and Assemble Carburetor

Carburetor – Clean, Inspect and Rebuild

Carburetor – Float Level Adjustment

Remove and Install Intake Manifold

Intake Manifold – Inspection

Remove and Install:Rocker Arm Covers;Rocker Arm Covers:Remove and Install

Remove and Install Rocker Arm Assembly

Inspect Rocker Arm Assembly

Inspect Push Rod

Remove and Install Cylinder Head

Disassemble and Assemble Cylinder Head and Valves

Inspect Cylinder Head and Valves

Analyze Valves

Recondition Valve Seats

Lap Valves

Remove and Install Engine

Remove, Inspect, and Install Flywheel

Remove and Install Stator

Remove and Install Breather

Remove, Inspect, and Install Crankcase Cover

Crankcase Cover – Oil Seal Replacement

Remove and Install Governor Arm

Remove and Install Piston and Connecting Rod

Disassemble, Inspect, and Assemble Piston and Connecting Rod

Analyze Piston Ring Wear

Analyze Piston Wear

Cylinder Bore Honing

Cylinder Bore Resizing

Remove and Install Camshaft and Tappet

Inspect Camshaft

Remove and Install Crankshaft

Inspect Crankshaft

Regrind Crankshaft

Replace Crankshaft Oil Seals

Analyze Crankshaft and Connecting Rod Wear

Inspect Cylinder Block

Remove and Install Oil Pump and Oil Pickup

Disassemble and Assemble Oil Pump and Oil Pickup

Inspect Oil Pump and Oil Pickup

Remove and Install Governor Assembly

Remove and Install Governor Cross Shaft

Remove and Install Ignition Coil

Remove and Install Pulser Coil

Remove and Install Starting Motor

Disassemble, Inspect, and Assemble Starting Motor

Engine – Diesel

Table of Contents

Specifications

General Specifications

Test and Adjustment Specifications

Repair Specifications

Torque Specifications

Tools and Materials

Special or Required Tools

Other Material

Theory of Operation

Cooling System Operation

Lubrication System Operation

Fuel and Air System Operation

Diagnostics

Diesel Engine Troubleshooting

Starting Motor Troubleshooting Guide

Tests and Adjustments

Check and Adjust 12V Alternator Drive Belt Tension – 2500B

Check and Adjust 48V Alternator Drive Belt Tension – 2500E

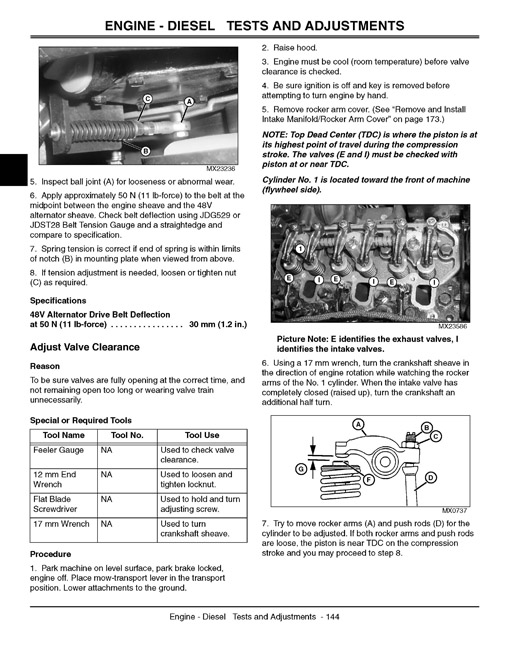

Adjust Valve Clearance

Check Valve Lift

Test Cylinder Compression

Test Engine Oil Pressure

Leak Test Air Intake System

Test Fuel Transfer Pump Pressure

Test Fuel Transfer Pump Flow

Leak Test Fuel System

Bleed Fuel System

Adjust Slow Idle Speed

Adjust Throttle Cable

Fast Idle Speed Check

Test Fuel Injection System

Test Fuel Injection Nozzle

Injection Pump Static Timing Check

Pressure Test Cooling System

Pressure Test Radiator Cap

Test Thermostat

Repair

Remove and Install 12V Alternator Drive Belt

Remove and Install 48V Alternator Drive Belt – 2500E

Remove and Install 48V Alternator Belt Tensioner – 2500E

Remove and Install Throttle Cable Assembly

Remove, Inspect and Install Radiator

Remove and Install Air Filter Restriction Indicator

Remove and Install Air Cleaner Assembly

Remove and Install Muffler

Remove and Install Exhaust Manifold

Remove and Install Thermostat

Remove and Install Coolant Temperature Switch

Remove and Install Engine

Remove and Install Glow Plug

Remove and Install Intake Manifold

Remove and Install Rocker Arm Assembly

Disassemble and Assemble Rocker Arm Assembly

Remove and Install Cylinder Head

Recondition Cylinder Head

Measure Piston-to-Cylinder Head Clearance

Remove and Install Piston and Connecting Rod

Connecting Rod Side Play Check

Check Connecting Rod Bearing Clearance

Cylinder Bore

Crankshaft Rear Oil Seal

Crankshaft Front Oil Seal

Crankshaft End Play Check

Crankshaft and Main Bearings

Crankshaft Main Bearing Clearance Check

Remove and Install Flywheel

Remove and Install Flywheel Housing

Camshaft

Remove, Inspect and Install Camshaft Follower

Remove and Install Timing Gear Cover

Remove and Install Idler Gear

Remove and Install Timing Gear Housing

Oil Pan, Crankcase Extension and Pickup Tube

Oil Pump

Remove and Install Coolant Pump (Thermostat Included)

Remove and Install Fuel Filter and Water Separator Assembly

Assemble Fuel Filter and Water Separator

Remove and Install Fuel Injection Pump

Remove, Inspect and Install Fuel Injection Nozzle

Remove and Install Fuel Shutoff Solenoid

Remove and Install Fuel Transfer Pump

Remove and Install Starting Motor

Remove and Install Starting Motor Solenoid

Remove and Install 48V Alternator – 2500E

Remove and Install

Electrical

Table of Contents

Specifications

Test Specifications

Tools

General Information

Theory of Operation Information

Diagnostic Information

Common Circuit Tests

Reading Electrical Schematics

Wire Color Abbreviation Chart

Component Location

Gasoline Engine Model 2500B

Gasoline Engine Model 2500E

Diesel Engine Model 2500B

Diesel Engine Model 2500E

Instrument Cluster

Schematics and Harnesses

Schematic and Wiring Harness Legend – Gasoline Engine

Main Electrical Schematic – 2500B Gasoline Engine (1 of 11)

Main Wiring Harness (W1) – Gasoline Engine (1 of 4)

Main Wiring Harness (W1) – Gasoline Engine Wire Code Table

Gasoline Engine Wiring Harnesses

Fuel Pump Harness (W14)

Fuel Pump Harness (W14) – Wire Code Table

Schematic and Wiring Harness Legend – Diesel Engine

Main Electrical Schematic – 2500B Diesel Engine (1 of 11)

Main Wiring Harness (W1) – Diesel Engine (1 of 4)

Main Wiring Harness (W1) – Diesel Engine Wire Code Table

Optional Third Wheel Assist Wiring Harness (W11)

Optional Third Wheel Assist Wiring Harness (W11) – Wire Code Table

Lighting Wiring Harness (W12)

Lighting Wiring Harness (W12) – Wire Code Table

Reel Motor Control Module Signal Harness (W15)

Reel Motor Control Module Signal Wiring Harness (W15) Wire Code Table – Model 2500E

Reel Motor Power Harness (W16)

Reel Motor Power Wiring Harness (W16) Wire Code Table – Model 2500E

Operation and Diagnostics – Gasoline Engine

Diagnostic Codes

Power Circuit Operation – Unswitched

Power Circuit Operation – Switched

Power Circuit Schematic

Power Circuit Diagnosis – Unswitched

Power Circuit Diagnosis – Switched

Cranking Circuit Operation

Cranking Circuit Schematic

Cranking Circuit Diagnosis

Run Circuit Operation – Operator On Seat

Run Circuit Schematic – Operator On Seat

Run Circuit Operation – Operator Off Seat

Run Circuit Schematic – Operator Off Seat

Run Circuit Operation – Engine Shutdown

Run Circuit Schematic – Engine Shutdown

Run Circuit Diagnosis

Raise-Lower Circuit Operation

Raise-Lower Circuit Schematic

Raise-Lower Circuit Diagnosis

Mow Circuit Operation 2500B

Mow Circuit Schematic 2500B

Mow Circuit Diagnosis

Backlap Circuit Operation 2500B

Backlap Circuit Schematic 2500B

Backlap Circuit Diagnosis

Mow Circuit Operation 2500E

Mow Circuit Schematic 2500E

Backlap Circuit Operation 2500E

Backlap Circuit Schematic 2500E

Mow-Backlap Circuit Diagnosis – Model 2500E

Reel Motor Circuit Diagnosis – Model 2500E

Charging Circuit Operation

Charging Circuit Schematic

Charging Circuit Diagnosis

Engine Oil Pressure Circuit Operation

Engine Oil Pressure Circuit Schematic

Engine Oil Pressure Circuit Diagnosis

Engine Coolant Temperature Circuit Operation

Engine Coolant Temperature Circuit Schematic

Engine Coolant Temperature Circuit Diagnosis

Hydraulic Oil Temperature Circuit Operation

Hydraulic Oil Temperature Circuit Schematic

Hydraulic Oil Temperature Circuit Diagnosis

Hour Meter Circuit Operation

Hour Meter Circuit

Hour Meter Circuit Diagnosis

Lighting Circuit Operation

Lighting Circuit Schematic

Lighting Circuit Diagnosis

Operation and Diagnostics – Diesel Engine

Diagnostic Codes

Power Circuit Operation – Unswitched

Power Circuit Operation – Switched

Power Circuit Schematic

Power Circuit Diagnosis – Unswitched

Power Circuit Diagnosis – Switched

Cranking Circuit Operation

Cranking Circuit Schematic

Cranking Circuit Diagnosis

Run Circuit Operation

Run Circuit Schematic – Operator On Seat

Run Circuit Schematic – Operator Off Seat

Run Circuit Diagnosis

Raise-Lower Circuit Operation

Raise-Lower Circuit Schematic

Raise-Lower Circuit Diagnosis

Mow Circuit Operation – Model 2500B

Mow Circuit Schematic – Model 2500B

Mow Circuit Diagnosis

Backlap Circuit Operation

Backlap Circuit Schematic – Model 2500B

Backlap Circuit Diagnosis

Mow Circuit Operation – Model 2500E

Mow Circuit Schematic – Model 2500E

Backlap Circuit Operation

Backlap Circuit Schematic – Model 2500E

Mow-Backlap Circuit Diagnosis – Model 2500E

Reel Motor Circuit Diagnosis – Model 2500E

Glow Plug Circuit Operation

Glow Plug Circuit Schematic

Glow Plug Circuit Diagnosis

Charging Circuit Operation

Charging Circuit Schematic

Charging Circuit Diagnosis

Engine Oil Pressure Circuit Operation

Engine Oil Pressure Circuit Schematic

Engine Oil Pressure Circuit Diagnosis

Engine Coolant Temperature Circuit Operation

Engine Coolant Temperature Circuit Schematic

Engine Coolant Temperature Circuit Diagnosis

Hydraulic Oil Temperature Circuit Operation

Hydraulic Oil Temperature Circuit Schematic

Hydraulic Oil Temperature Circuit Diagnosis

Hour Meter Circuit Operation

Hour Meter Circuit Schematic

Hour Meter Circuit Diagnosis

Lighting Circuit Operation

Lighting Circuit Schematic

Lighting Circuit Diagnosis

Tests and Adjustments

Ground Circuit Test

Interlock Module Check

Battery Test

Charge Battery

Battery Load Test

Regulated Voltage Output Test

Unregulated Voltage Output Test- Gasoline Engine

Unregulated Voltage Output Test – Diesel Engine

Starting Motor Cranking Amperage Draw Test

Starting Motor Solenoid Test – Gasoline Engine

Starting Motor Solenoid Test- Diesel Engine

Pulser Coil Test- Gasoline Engine

Ignition Coil Test – Gasoline Engine

Ignition Module Test – Gasoline Engine

Glow Plug Test – Diesel

Fuse Test

Diode Test

Resistor Test

Electrical Relay

Key Switch Test

Park Brake and Mow-Transport Switch

Raise-Lower Switch Test

Seat Switch Test

Mow Solenoid Test

Raise or Lower Solenoid Test

Backlap Switch Test – Model 2500B

Backlap Switch Test- Model 2500E

Hydraulic Temperature Switch Test

Engine Oil Pressure Switch Test – Gasoline Engine

Fuel Shutoff Solenoid Test – Gasoline Engine

Fuel Shutoff Solenoid Test – Diesel Engine

Engine Oil Pressure Switch Test – Diesel Engine

Headlight Switch Test (Optional)

Reel Motor Forward-Reverse Switch Test – Model 2500E

Reel Motor Speed Control Test – Model 2500E

Engine Coolant Temperature Switch Test

Reel Motor Test – Model 2500E

Reel Motor Power Draw Test – Model 2500E

Repair

Remove and Install Battery

Clean Battery

Remove METRI-PACK

Replace METRI-PACK

Remove WEATHER PACK

Repair Reel Motor Wiring Harness

Hydrostatic Power Train

Table of Contents

Specifications

Test and Adjustment Specifications

Repair Specifications

Tools and Materials

Tools

Materials

Component Location

Hydrostatic Drive Components

Hydraulic System Hose Routing – Motor Drive System

Theory of Operation

Hydrostatic Transmission

Hydrostatic Schematics

Main Hydrostatic Diagram

Third Wheel Assist Hydrostatic Diagram

Diagnostics

Troubleshooting Hints

Hydrostatic Power Train Troubleshooting

Tests and Adjustments

Test Charge Pressure

Test Hydrostatic Transmission Pump Flow

Adjust Hydrostatic Pump Control Linkage

Mowing Speed Adjustment

Repair

Remove and Install Mow-Transport Cable and Lever Assembly

Mow-Transport Switch and Lever Repair

Remove and Install Hydrostatic Pump Control Cable

Forward and Reverse Travel Pedal Repair

Remove and Install Hydrostatic Pump Assembly – Gasoline Engine

Remove and Install Hydrostatic Pump Assembly – Diesel Engine

Disassemble Hydrostatic Pump

Inspect Hydrostatic Pump

Assemble Hydrostatic Pump

Remove and Install Front Wheel Motors

Remove and Install Third Wheel Assist Motor

Disassemble and Inspect Wheel Motors

Assemble Wheel Motors

Wheel Motor Final Checks

Remove and Install Third Wheel Assist Valve

Repair Third Wheel Assist Drive Valve

Hydraulics

Table of Contents

Specifications

Test and Adjustment Specifications

Hydraulic:Repair Specifications;Specifications:Hydraulic Repair

Tools and Materials

Hydraulic:Special or Required Tools

Component Location

Hydraulic System Component Location

Hydraulic System Hose Routing – Steering System

Hydraulic System Hose Routing – Reel Drive System – 2500B

Hydraulic System Hose Routing – Cutting Unit Lift System

Schematics and Harnesses

JIC Hydraulic Circuit Symbols

Hydraulic System Schematic

Hydraulic System Schematic – With Optional Equipment

Operation and Diagnostics

Reel Drive System – Mow Operation – 2500B

Reel Drive System – Backlap Operation – 2500B

Cutting Unit Lift System Operation – Raise

Cutting Unit Lift System Operation – Lower and Float

Leak Detection System Operation (Optional)

Reel Drive Diagnosis – 2500B

Lift System Diagnosis – All Machines

Tests and Adjustments

Warm Up Hydraulic Oil

Bleed Hydraulic System

Test Lift Pump Oil Flow

Test Reel Drive Pump Oil Flow – 2500B

Test Reel Motor Case Drain

Test and Adjust Mow Valve Relief Valve – 2500B

Adjust Front Lift Arm

Adjust Rear Lift Arm

Repair

Remove and Install Hydraulic Reservoir Expansion Tank

Remove and Install Hydraulic Reservoir

Remove and Install Oil Cooler – 2500B

Remove and Install Raise-Lower Lever Assembly

Repair Raise-Lower Lever Assembly

Remove and Install Hydraulic Pump Assembly

Disassemble and Inspect Hydraulic Pump Assembly

Assemble Hydraulic Pump Assembly

Remove and Install Reel Motor – 2500B

Disassemble and Inspect Reel Motor – 2500B

Assemble Reel Motor – 2500B

Remove and Install Mow-Backlap Valve

Disassemble and Assemble Mow-Backlap Valve

Remove and Install Lift Valve

Disassemble and Assemble Lift Valve

Remove and Install Front Lift Cylinder

Disassemble and Assemble Front Lift Cylinder

Remove and Install Center (Rear) Lift Cylinder

Disassemble and Assemble Center (Rear) Lift Cylinder

Repair Center (Rear) Lift Arm

Repair Front Lift Arms

Brakes

Table of Contents

Specifications

Brake System:Adjustment Specifications;Adjustment Specifications:Brake System;Specifications:Brake S

Repair Specifications

Component Location

Brake System:Component Location;Component Location:Brake System

Theory of Operation

Brake System Operation

Diagnostics

Brake System:Troubleshooting;Troubleshooting:Brake System

Tests and Adjustments

Adjust Park Brake Linkage

Adjust Park Brake Switch

Repair

Remove and Install Park Brake

Disassemble and Assemble Park Brake

Pedal and Lock Linkage:Disassemble and Assemble;Disassemble and Assemble:Pedal and Lock Linkage

Park Brake:Disassemble and Assemble:Linkage;Disassemble and Assemble:Park Brake:Linkage

Steering

Table of Contents

Specifications

Test and Adjustment Specifications

Repair Specifications

Tools and Materials

Special or Essential Tools

Other Materials

Component Location

Steering System Component Location

Theory of Operation

Steering System Operation – Neutral

Steering System Operation – Power Turn

Steering System Operation – Manual Turn

Diagnostics

Steering Not Driving Straight

Steering Wheel Vibration

Sluggish Steering Response

High Steering Effort in Both Directions

Steering Effort Is Not Smooth

Machine Continues to Turn after Steering Wheel Has Returned to Center Position

Lost Motion at Steering Wheel

Steering Operation Reversed

Hydraulic Oil Foams

Tests and Adjustments

Test Steering System Leakage

Test Steering Valve Leakage

Test Steering-Charge Pump Flow

Test Steering Relief Valve

Repair

Remove and Install Steering Wheel

Remove and Install Steering Column Cover

Remove and Install Steering Column Tilt Pawl

Remove and Install Steering Valve

Steering Cylinder:Removal and Installation; Cylinder:Steering, Removal and Installation

Disassemble and Assemble Steering Cylinder

Remove and Install Steering Clevis

Remove and Install Steering Clevis (Third Wheel Assist)

Attachments

Table of Contents

Specifications

General Specifications

Adjustment Specifications

Repair Specifications

Tools and Materials:Special or Essential Tools;Tools and Materials:Other Materials;Tools and Materia

Special or Essential Tools

Dealer Fabricated Tools

Other Materials

Component Location

Cutting Unit

Greens and Turf Conditioner (GTC)

Vertical Cutting Unit

Theory of Operation

Reel and Bed Knife Grinding

Vertical Cutting Unit

Rollers

Performance Variables

Diagnostics

Reel Attachments:Troubleshooting;Troubleshooting:Reel Attachments

Tests and Adjustments

Adjust Reel Speed

Adjust Reel-to-Bed Knife

Backlapping and Reel-to-Bed Knife Adjustment

Backlapping Procedure

Tests and Adjustments:Grinding:Reel and Bed Knife;Grinding:Reel and Bed Knife;Reel and Bed Knife:Gri

Adjust Height-of-Cut Range

Adjust Front Roller

Adjust Height-of-Cut (HOC)

Adjust Greens and Turf Conditioner (GTC)

Adjust Cutting Shield

Adjust Depth-of-Cut – Vertical Cutting Units

Adjust Power Brush

Repair

Inspect Reel and Bed Knife

Remove and Install Electric Reel Motor – 2500E

Remove and Install Cutting Unit

Remove and Install Reel Drive Belt – 2500E

Remove and Install Reel

Disassemble and Inspect Bearing Housing

Assemble Bearing Housing

Repair Belt Drive Housing – 2500E

Remove and Install Bed Knife

Remove and Install Front Roller

Remove and Install Rear Roller

Disassemble and Assemble Roller

Remove and Install Greens and Turf Conditioner

Disassemble and Inspect Greens and Turf Conditioner

Remove and Install Power Brush

Disassemble and Inspect Power Brush

Remove and Install Vertical Cutting Unit

Remove and Install Reel Assembly – Vertical Cutting Unit

Disassemble and Inspect Reel Assembly – Vertical Cutting Unit

Assemble Reel – Vertical Cutting Unit

Disassemble and Inspect Bearing Housing – Vertical Cutting Unit

Assemble Bearing Housing – Vertical Cutting Unit

Remove and Install Front Roller – Vertical Cutting Unit

Remove Rear Roller – Vertical Cutting Unit

Replace Roller Bearing – Vertical Cutting Unit

Miscellaneous

Table of Contents

Repair:Specifications;Specifications:Repair

Repair Specifications

Repair

Remove and Install Roll-Over Protective Structure (ROPS)

Remove and Install Hood

Disassemble and Assemble Hood

Remove and Install Front Wheels

Remove and Install Rear Wheel

Remove and Install Rear Wheel (Third Wheel Assist)

Disassemble and Assemble Rear Wheel

Disassemble and Assemble Console

Disassemble and Assemble Seat and Platform

Fuel Tank:Remove and Install:Gasoline;Remove and Install:Fuel Tank:Gasoline

Fuel Tank:Remove and Install:Diesel;Remove and Install:Fuel Tank:Diesel

Fuel Tank:Disassemble and Assemble;Disassemble and Assemble:Fuel Tank

Numerics

Index

Reviews

There are no reviews yet.