Description

John Deere TM1527 1800 Utility Vehicle Technical Manual

432 Pages – PDF – 25.2mb

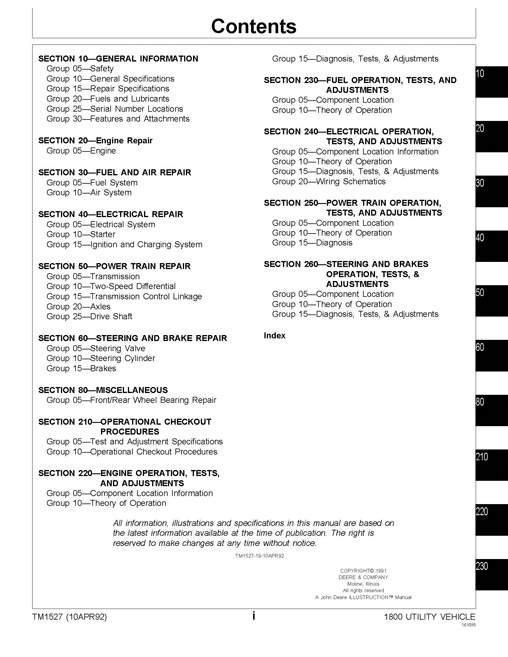

Contents –

TM1527 – 1800 Utility Vehicle.

Introduction.

Contents.

SECTION 10 GENERAL INFORMATION.

Safety.

RECOGNIZE SAFETY INFORMATION.

UNDERSTAND SIGNAL WORDS.

FOLLOW SAFETY INSTRUCTIONS.

HANDLE FLUIDS SAFELY—AVOID FIRES.

PREVENT BATTERY EXPLOSIONS.

PREPARE FOR EMERGENCIES.

PREVENT ACID BURNS.

SERVICE COOLING SYSTEM SAFELY.

PARK MACHINE SAFELY.

SUPPORT MACHINE PROPERLY.

WEAR PROTECTIVE CLOTHING.

WORK IN CLEAN AREA.

SERVICE MACHINES SAFELY.

WORK IN VENTILATED AREA.

ILLUMINATE WORK AREA SAFELY.

REPLACE SAFETY SIGNS.

USE PROPER LIFTING EQUIPMENT.

SERVICE TIRES SAFELY.

AVOID HARMFUL ASBESTOS DUST.

AVOID HEATING NEAR PRESSURIZED FLUID LINES.

REMOVE PAINT BEFORE WELDING OR HEATING.

USE PROPER TOOLS.

DISPOSE OF WASTE PROPERLY.

LIVE WITH SAFETY.

General Specifications.

MACHINE SPECIFICATIONS.

MACHINE SPECIFICATIONS—CONTINUED.

Repair Specifications.

REPAIR SPECIFICATIONS.

REPAIR SPECIFICATIONS—CONTINUED.

SERVICE RECOMMENDATIONS FOR O-RING BOSS FITTINGS.

METRIC BOLT AND CAP SCREW TORQUE VALUES.

UNIFIED INCH BOLT AND CAP SCREW TORQUE VALUES.

Fuels and Lubricants.

FUEL.

STORING FUEL.

GASOLINE ENGINE OIL.

ENGINE COOLANT.

HYDROSTATIC DRIVE OIL.

EXTREME PRESSURE OR MULTIPURPOSE GREASE.

LUBRICANT STORAGE.

ALTERNATIVE LUBRICANTS.

Serial Number Locations.

SERIAL NUMBERS.

RECORD PRODUCT IDENTIFICATION NUMBER.

RECORD ENGINE SERIAL NUMBER.

RECORD DIFFERENTIAL SERIAL NUMBER.

RECORD HYDROSTATIC TRANSMISSION SERIAL NUMBER.

Features and Attachments.

FEATURES AND ATTACHMENTS INFORMATION.

STANDARD FEATURES.

SECTION 20 ENGINE REPAIR.

Engine.

JOHN DEERE ENGINE REPAIR—USE CTM39.

USE PROPER LIFTING EQUIPMENT.

REMOVE ENGINE.

USE PROPER LIFTING EQUIPMENT.

INSTALL ENGINE.

REPLACE COOLING FAN BELT.

SECTION 30 FUEL AND AIR REPAIR.

Fuel System.

CARBURETOR REPAIR – USE CTM39.

REPLACE FUEL FILTER.

REPLACE FUEL TRANSFER PUMP.

REPLACE FUEL LINES.

REPLACE THROTTLE CONTROL LEVER AND CABLE.

REPLACE CHOKE CABLE.

Air System.

REMOVE, INSPECT, AND INSTALL AIR CLEANER ELEMENTS.

SECTION 40 ELECTRICAL REPAIR.

Electrical System.

STATOR REPAIR – USE CTM39.

PREVENT BATTERY EXPLOSIONS.

PREVENT ACID BURNS.

DISPOSE OF WASTE PROPERLY.

REMOVE AND INSTALL BATTERY.

REPLACE BATTERY CABLES.

REPLACE IGNITION KEY SWITCH.

REPLACE VOLTAGE REGULATOR.

REPLACE INSTRUMENT INDICATOR LAMPS.

REPLACE STARTER INTERLOCK SWITCH.

REPLACE SEAT SAFETY SWITCH.

REPLACE OIL PRESSURE SENDER.

REPLACE COOLANT TEMPERATURE SENSOR.

REPLACE FUSIBLE LINK.

Starter.

REMOVE AND INSTALL STARTER.

STARTER REPAIR – USE CTM39.

Ignition and Charging System.

SPECIAL OR ESSENTIAL TOOLS.

SERVICE PARTS KITS.

REPLACE CONNECTOR BODY—BLADE TERMINALS.

REPLACE WEATHER PACK™ CONNECTOR.

INSTALL WEATHER PACK CONTACT.

SECTION 50 POWER TRAIN REPAIR.

Transmission.

SERVICE PARTS KITS.

REMOVE TRANSMISSION.

DISASSEMBLE AND INSPECT TRANSMISSION.

CROSS SECTION OF TRANSMISSION.

ASSEMBLE TRANSMISSION.

INSTALL TRANSMISSION.

REMOVE AND INSTALL CHARGE PUMP.

DISASSEMBLE AND INSPECT CHARGE PUMP.

ASSEMBLE CHARGE PUMP.

REMOVE, INSPECT, AND INSTALL CHARGE RELIEF VALVE.

REMOVE AND INSTALL IMPLEMENT RELIEF VALVE.

Two-Speed Differential.

SHOP EQUIPMENT AND TOOLS.

REMOVE DIFFERENTIAL.

DISASSEMBLE DIFFERENTIAL.

CROSS SECTION OF TWO-SPEED DIFFERENTIAL.

ASSEMBLE DIFFERENTIAL.

INSTALL DIFFERENTIAL.

Transmission Control Linkage.

REMOVE TRANSMISSION CONTROL LINKAGE (SHIFTER).

INSTALL TRANSMISSION CONTROL LINKAGE (SHIFTER).

Axles.

REMOVE AND INSPECT REAR AXLES.

INSTALL REAR AXLES.

Drive Shaft.

REMOVE DRIVE SHAFT.

DISASSEMBLE DRIVE SHAFT.

ASSEMBLE DRIVE SHAFT.

INSTALL DRIVE SHAFT.

SECTION 60 STEERING AND BRAKE REPAIR.

Steering Valve.

FABRICATED TOOLS.

SERVICE PARTS KITS.

SPECIFICATIONS.

REMOVE STEERING VALVE.

DISASSEMBLE CONTROL VALVE SECTION.

DISASSEMBLE METERING SECTION.

DISASSEMBLE STEERING TUBE SECTION.

CROSS SECTION OF STEERING VALVE.

ASSEMBLE STEERING TUBE SECTION.

ASSEMBLE METERING SECTION.

ASSEMBLE CONTROL VALVE SECTION.

INSTALL STEERING VALVE.

AVOID HIGH-PRESSURE FLUIDS.

Steering Cylinder.

OTHER MATERIALS.

AVOID HIGH-PRESSURE FLUIDS.

REMOVE STEERING CYLINDER.

REPAIR STEERING CYLINDER.

INSTALL STEERING CYLINDER.

Brakes.

SUPPORT MACHINE PROPERLY.

AVOID HARMFUL ASBESTOS DUST.

REMOVE BRAKES.

INSTALL BRAKES.

REMOVE BRAKE PEDAL.

INSTALL BRAKE PEDAL.

REMOVE AND INSPECT NEUTRAL RETURN LINKAGE.

REMOVE AND INSPECT PARK BRAKE LINKAGE.

INSTALL PARK BRAKE LINKAGE.

SECTION 80 MISCELLANEOUS.

Front.

FRONT WHEEL BEARING REPAIR.

REAR WHEEL BEARING REPAIR.

AVOID HIGH-PRESSURE FLUIDS.

FRONT AXLE SERVICE.

SECTION 210 OPERATIONAL CHECKOUT PROCEDURES.

Test and Adjustment Specifications.

TEST AND ADJUSTMENT SPECIFICATIONS.

Operational Checkout Procedures.

OPERATIONAL CHECKOUT PROCEDURES.

ENGINE OIL CHECK.

COOLING SYSTEM CHECK.

FUEL SYSTEM CHECK.

AIR INTAKE SYSTEM CHECK.

ELECTRICAL SYSTEM CHECK.

HYDRAULIC SYSTEM CHECK.

MISCELLANEOUS CHECKS.

CHECKING INDICATOR LAMPS.

TRANSFER PUMP CHECK.

STARTING CIRCUIT CHECK.

STARTING CIRCUIT CHECK—CONTINUED.

ENGINE PERFORMANCE CHECK.

CHOKE LEVER CHECK.

SEAT SWITCH CHECK FOR ENGINE CIRCUIT.

TRANSMISSION FORWARD—REVERSE CHECK.

TRANSMISSION NEUTRAL RETURN CHECK.

POWER STEERING CHECK.

CHECKOUT PROCEDURE COMPLETE.

SECTION 220 ENGINE OPERATION, TESTS, AND ADJUSTMENTS.

Component Location Information.

COMPONENT LOCATION INFORMATION.

ENGINE COMPONENTS.

LUBRICATION SYSTEM COMPONENTS.

ENGINE COOLING SYSTEM COMPONENTS.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

CRANKCASE BREATHER OPERATION.

LUBRICATION SYSTEM OPERATION.

OIL FILTER OPERATION.

ENGINE COOLING SYSTEM OPERATION.

Diagnosis, Tests, & Adjustments.

DIAGNOSTIC INFORMATION.

ENGINE TURNS OVER BUT WILL NOT START.

ENGINE BACKFIRES—WHILE RUNNING.

ENGINE BACKFIRES THROUGH MUFFLER WHEN SHUT OFF.

ENGINE MISSES.

ENGINE SURGING.

ENGINE FLOODING.

LACK OF FUEL IN CARBURETOR.

ENGINE STOPS WHEN HOT.

ENGINE EXHAUST SMOKES—BLACK OR GREY.

ENGINE SMOKES BLUE OR USES EXCESS OIL.

ENGINE USES TOO MUCH FUEL.

ENGINE HAS EXCESS NOISE OR VIBRATIONS.

ENGINE HAS LOW OIL PRESSURE.

ENGINE COOLANT OPERATING TEMPERATURE INCORRECT.

OIL IN COOLANT OR COOLANT IN OIL.

RADIATOR BUBBLE TEST.

COOLING SYSTEM TEST.

RADIATOR CAP PRESSURE TEST.

FUEL TRANSFER PUMP FLOW TEST.

FUEL TRANSFER PUMP PRESSURE TEST.

ENGINE OIL PRESSURE TEST.

CYLINDER COMPRESSION PRESSURE TEST.

IGNITION SPARK TEST.

THROTTLE LEVER ADJUSTMENT.

THROTTLE CABLE ADJUSTMENT.

CHOKE ADJUSTMENT.

CARBURETOR IDLE MIXTURE SCREW ADJUSTMENT.

GOVERNOR ADJUSTMENT.

SLOW IDLE ADJUSTMENT.

FAST IDLE ADJUSTMENT.

VALVE CLEARANCE ADJUSTMENT.

COOLING FAN DRIVE BELT ADJUSTMENT.

SECTION 230 FUEL OPERATION, TESTS, AND ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

FUEL SYSTEM COMPONENTS.

CARBURETOR COMPONENTS.

AIR INTAKE SYSTEM COMPONENTS.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

FUEL SYSTEM OPERATION.

CARBURETOR OPERATION.

CARBURETOR OPERATION—MAIN CIRCUIT.

CARBURETOR OPERATION—IDLE CIRCUIT (NO LOAD).

CARBURETOR OPERATION—IDLE CIRCUIT (ACCELERATION).

CARBURETOR OPERATION—START CIRCUIT (CHOKE).

GOVERNOR OPERATION.

GOVERNOR OPERATION—STARTING.

GOVERNOR OPERATION—HIGH IDLE.

AIR INTAKE SYSTEM OPERATION.

SECTION 240 ELECTRICAL OPERATION, TESTS, AND ADJUSTMENTS.

Component Location Information.

COMPONENT LOCATION INFORMATION.

ELECTRICAL COMPONENTS.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

WIRE COLOR CHART.

CRANKING CIRCUIT OPERATION.

IGNITION CIRCUIT OPERATION.

IGNITION CIRCUIT OPERATION-CONTINUED.

CHARGING CIRCUIT OPERATION.

LOW OIL PRESSURE LAMP CIRCUIT OPERATION.

COOLANT TEMPERATURE LAMP CIRCUIT OPERATION.

Diagnosis, Tests, & Adjustments.

DIAGNOSTIC INFORMATION.

CRANKING CIRCUIT TEST POINTS.

IGNITION CIRCUIT TEST POINTS.

COMMON CIRCUIT TEST.

TEST GROUND CIRCUIT.

BATTERY TEST.

CHARGE BATTERY.

LOAD TEST BATTERY.

REGULATED AMPERAGE TEST.

REGULATED VOLTAGE TEST.

UNREGULATED VOLTAGE OUTPUT TEST.

TEST STARTER SOLENOID.

TEST STARTER AMP DRAW.

TEST STARTER NO-LOAD AMPERAGE.

PULSER COIL TEST.

TEST IGNITION COIL.

TEST IGNITION MODULE.

SPARK PLUG CAP TEST.

ADJUST SPARK PLUG GAP.

TEST STARTER INTERLOCK SWITCH.

TEST SEAT SWITCH.

TEST KEY SWITCH.

TEST RELAY.

TEST DIODE.

OIL PRESSURE INDICATOR TEST.

COOLANT TEMPERATURE INDICATOR TEST.

TACHOMETER FAILURE.

Wiring Schematics.

SCHEMATICS INFORMATION.

ELECTRICAL SCHEMATIC LEGEND.

SECTION 250 POWER TRAIN OPERATION, TESTS, AND ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

POWER TRAIN COMPONENT LOCATION.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

TRANSMISSION OPERATION—NEUTRAL.

TRANSMISSION OPERATION—FORWARD.

TRANSMISSION OPERATION—REVERSE.

DIFFERENTIAL OPERATION.

Diagnosis.

DIAGNOSTIC INFORMATION.

MACHINE MOVES IN ONE DIRECTION ONLY OR FREEWHEELS.

MACHINE WILL NOT MOVE IN EITHER DIRECTION.

TRANSMISSION OPERATION IS SLOW, ERRATIC, OR HAS LOW POWER, OR SPEED WILL NOT INCREASE.

MACHINE WILL NOT REACH FULL SPEED.

TRANSMISSION OPERATING HOT.

HYDRAULIC OIL WARM-UP PROCEDURE.

TRANSMISSION OIL TEMPERATURE CHECK.

CHECK VALVE DEBRIS CHECK.

CHARGE PUMP PRESSURE TEST.

CHARGE RELIEF VALVE ADJUSTMENT.

IMPLEMENT RELIEF PRESSURE TEST.

CHARGE PUMP FLOW TEST.

TRANSMISSION NEUTRAL RETURN ADJUSTMENT.

TRANSMISSION NEUTRAL ADJUSTMENT.

TRANSMISSION NEUTRAL ADJUSTMENT—CONTINUED.

SECTION 260 STEERING AND BRAKES OPERATION, TESTS, & ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

STEERING SYSTEM COMPONENT LOCATION.

BRAKE SYSTEM COMPONENT LOCATION.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

STEERING VALVE OPERATION—NEUTRAL.

STEERING VALVE OPERATION—LEFT HAND TURN.

STEERING VALVE OPERATION—RIGHT HAND TURN.

BRAKE SYSTEM OPERATION.

Diagnosis, Tests, & Adjustments.

DIAGNOSTIC INFORMATION.

STEERING WANDERS.

STEERING SHIMMY.

SLUGGISH STEERING RESPONSE.

EXCESSIVE STEERING WHEEL FREE PLAY.

HIGH STEERING EFFORT IN ONE DIRECTION.

HIGH STEERING EFFORT IN BOTH DIRECTIONS.

WHEELS DO NOT HIT STOP.

STEERING EFFORT IS ERRATIC.

WHEELS CONTINUE TURNING AFTER STEERING WHEEL IS STOPPED.

BRAKES DO NOT OPERATE PROPERLY.

HYDRAULIC OIL WARM-UP PROCEDURE.

STEERING SYSTEM LEAKAGE TEST.

STEERING VALVE LEAKAGE TEST.

STEERING VALVE LEAKAGE TEST — CONTINUED.

TOE-IN ADJUSTMENT.

BRAKE SHOE ADJUSTMENT.

BRAKE LINKAGE AND PEDAL FREE-PLAY ADJUSTMENT.

PARK BRAKE ADJUSTMENT.

INDEX.

Reviews

There are no reviews yet.