Description

John Deere TM1525 1200 Bunker and Field Rake Technical Manual

23.5mb – PDF – 476 Pages

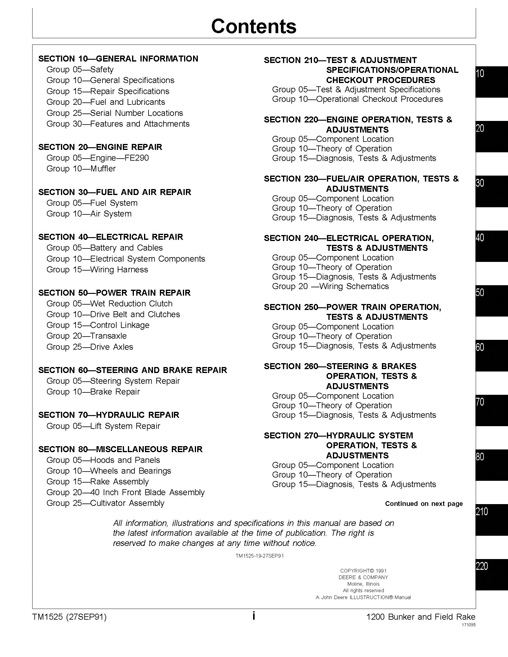

Contents in Detail –

TM1525 – 1200 Bunker and Field Rake.

Introduction.

Contents.

SECTION 10 GENERAL INFORMATION.

Safety.

RECOGNIZE SAFETY INFORMATION.

UNDERSTAND SIGNAL WORDS.

FOLLOW SAFETY INSTRUCTIONS.

HANDLE FLUIDS SAFELY—AVOID FIRES.

PREVENT BATTERY EXPLOSIONS.

PREPARE FOR EMERGENCIES.

PREVENT ACID BURNS.

AVOID HIGH-PRESSURE FLUIDS.

PARK MACHINE SAFELY.

SUPPORT MACHINE PROPERLY.

WEAR PROTECTIVE CLOTHING.

SERVICE MACHINES SAFELY.

WORK IN VENTILATED AREA.

WORK IN CLEAN AREA.

ILLUMINATE WORK AREA SAFELY.

REMOVE PAINT BEFORE WELDING OR HEATING.

AVOID HEATING NEAR PRESSURIZED FLUID LINES.

REPLACE SAFETY SIGNS.

USE PROPER LIFTING EQUIPMENT.

SERVICE TIRES SAFELY.

AVOID HARMFUL ASBESTOS DUST.

PRACTICE SAFE MAINTENANCE.

USE PROPER TOOLS.

DISPOSE OF WASTE PROPERLY.

LIVE WITH SAFETY.

General Specifications.

MACHINE SPECIFICATIONS.

ATTACHMENT SPECIFICATIONS.

Repair Specifications.

REPAIR SPECIFICATIONS.

TUNE-UP SPECIFICATIONS.

TUNE-UP ADJUSTMENTS.

SERVICE RECOMMENDATIONS FOR O-RING BOSS FITTINGS.

METRIC BOLT AND CAP SCREW TORQUE VALUES.

UNIFIED INCH BOLT AND CAP SCREW TORQUE VALUES.

Fuel and Lubricants.

FUEL.

STORING FUEL.

GASOLINE ENGINE.OIL.

TRANSAXLE OIL.

EXTREME PRESSURE OR MULTIPURPOSE GREASE.

LUBRICANT STORAGE.

ALTERNATIVE LUBRICANTS.

Serial Number Locations.

SERIAL NUMBERS.

PRODUCT IDENTIFICATION NUMBER LOCATION.

ENGINE SERIAL NUMBER LOCATION.

TRANSAXLE SERIAL NUMBER LOCATION.

HYDRAULIC PUMP SERIAL NUMBER LOCATION (OPTIONAL).

Features and Attachments.

FEATURES & ATTACHMENTS.

MACHINE FEATURES.

“K” SERIES FE290R ENGINE FEATURES.

POWER TRAIN FEATURES.

ELECTRICAL SYSTEM FEATURES.

RAKE FEATURES.

OPTIONAL ATTACHMENTS AND KITS.

SECTION 20 ENGINE REPAIR.

Engine¯FE290.

JOHN DEERE ENGINE REPAIR—USE CTM5.

LOWER ALL ATTACHMENTS.

REMOVE ENGINE.

INSTALL ENGINE.

Muffler.

LOWER ALL ATTACHMENTS.

REMOVE AND INSTALL MUFFLER.

SECTION 30 FUEL AND AIR REPAIR.

Fuel System.

CARBURETOR REPAIR—USE CTM5.

SERVICE PARTS KITS.

LOWER ALL ATTACHMENTS.

REMOVE AND INSTALL CARBURETOR.

REMOVE, INSPECT AND INSTALL FUEL PUMP.

REPLACE FUEL FILTER.

REMOVE, INSPECT AND INSTALL FUEL TANK.

REPLACE FUEL HOSES.

REPLACE ACCELERATOR CABLE AND HOUSING.

INSPECT AND REPAIR ACCELERATOR PEDAL ASSEMBLY.

REMOVE AND INSTALL CHOKE KNOB AND CABLE.

Air System.

LOWER ALL ATTACHMENTS.

REMOVE AND INSTALL AIR CLEANER.

REMOVE, INSPECT AND INSTALL AIR CLEANER ELEMENT—STANDARD AIR CLEANER.

REMOVE, INSPECT AND INSTALL AIR CLEANER ELEMENTS—HEAVY DUTY AIR CLEANER.

SECTION 40 ELECTRICAL REPAIR.

Battery and Cables.

LOWER ALL ATTACHMENTS.

REMOVE AND INSTALL BATTERY.

REPLACE BATTERY CABLES.

Electrical System Components.

STARTER AND ENGINE IGNITION.CTM5.

LOWER ALL ATTACHMENTS.

REMOVE AND INSTALL STARTER.

REPLACE VOLTAGE REGULATOR.

REPLACE REGULATOR CIRCUIT BREAKER.

REPLACE KEY SWITCH CIRCUIT BREAKER.

REPLACE HYDRAULIC PUMP CIRCUIT BREAKER (OPTIONAL).

REPLACE HYDRAULIC PUMP RELAY(S).

REPLACE KEY SWITCH.

REPLACE FRONT LIGHT SWITCH (OPTIONAL).

REPLACE VOLTMETER.

REPLACE HOURMETER.

REPLACE HYDRAULIC PUMP SWITCH (OPTIONAL).

REPLACE NEUTRAL START SWITCH.

REPLACE FRONT LIGHT.

REPLACE HYDRAULIC PUMP MOTOR (OPTIONAL).

Wiring Harness.

SPECIAL OR ESSENTIAL TOOLS.

LOWER ALL ATTACHMENTS.

REPLACE CONNECTOR BODY—BLADE TERMINALS.

REPLACE WEATHER PACK™ CONNECTOR.

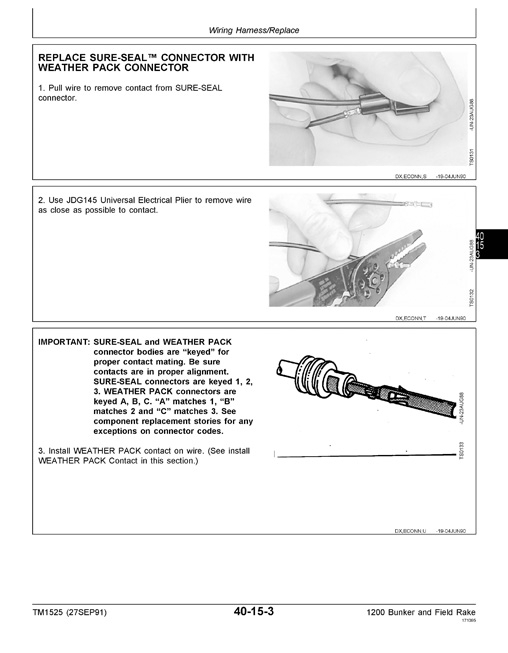

REPLACE SURE-SEAL™ CONNECTOR WITH WEATHER PACK CONNECTOR.

INSTALL WEATHER PACK CONTACT.

REPLACE MACHINE WIRING HARNESS.

REPLACE HYDRAULIC PUMP WIRING HARNESS (OPTIONAL).

SECTION 50 POWER TRAIN REPAIR.

Wet Reduction Clutch.

LOWER ALL ATTACHMENTS.

REMOVE WET REDUCTION CLUTCH.

DISASSEMBLE AND INSPECT WET REDUCTION CLUTCH.

WET REDUCTION CLUTCH CROSS SECTION.

ASSEMBLE WET REDUCTION CLUTCH.

INSTALL WET REDUCTION CLUTCH.

Drive Belt and Clutches.

SPECIAL OR ESSENTIAL TOOLS.

LOWER ALL ATTACHMENTS.

REMOVE DRIVE BELT.

INSTALL DRIVE BELT.

REMOVE AND INSTALL DRIVE CLUTCH.

DISASSEMBLE DRIVE CLUTCH.

INSPECT AND REPAIR DRIVE CLUTCH.

ASSEMBLE DRIVE CLUTCH.

REMOVE AND INSTALL DRIVEN CLUTCH.

DISASSEMBLE DRIVEN CLUTCH.

INSPECT DRIVEN CLUTCH.

ASSEMBLE DRIVEN CLUTCH.

Control Linkage.

LOWER ALL ATTACHMENTS.

REPLACE TRANSAXLE SHIFT CABLES AND HOUSINGS.

INSPECT AND REPAIR GEAR SHIFT PEDALS.

INSPECT AND REPAIR DIFFERENTIAL LOCK PEDAL AND LINKAGE.

Transaxle.

LOWER ALL ATTACHMENTS.

REMOVE TRANSAXLE.

REMOVE TRANSAXLE EXTERNAL COMPONENTS.

DISASSEMBLE AND INSPECT TRANSAXLE.

ASSEMBLE TRANSAXLE.

INSTALL TRANSAXLE EXTERNAL COMPONENTS.

INSTALL TRANSAXLE.

Drive Axles.

REMOVE, INSPECT AND INSTALL DRIVE AXLES AND BEARINGS.

SECTION 60 STEERING AND BRAKE REPAIR.

Steering System Repair.

LOWER ALL ATTACHMENTS.

REMOVE, INSPECT AND INSTALL STEERING SHAFT.

REMOVE, INSPECT AND INSTALL STEERING FORK ASSEMBLY.

Brake Repair.

LOWER ALL ATTACHMENTS.

REMOVE AND INSTALL BRAKE CALIPER.

DISASSEMBLE, INSPECT AND ASSEMBLE BRAKE CALIPER.

REMOVE, INSPECT AND INSTALL BRAKE DISK.

REPLACE BRAKE CABLE AND HOUSING.

INSPECT AND REPAIR BRAKE PEDAL ASSEMBLY.

BRAKE PAD CONTACT ADJUSTMENT.

SECTION 70 HYDRAULIC REPAIR.

Lift System Repair.

LOWER ALL ATTACHMENTS.

REMOVE AND INSTALL HYDRAULIC PUMP (OPTIONAL).

DISASSEMBLE AND INSPECT HYDRAULIC PUMP.

ASSEMBLE HYDRAULIC PUMP.

REMOVE AND INSTALL LIFT CYLINDER.

INSPECT AND REPLACE HYDRAULIC HOSES AND COUPLERS.

SECTION 80 MISCELLANEOUS REPAIR.

Hoods and Panels.

LOWER ALL ATTACHMENTS.

REMOVE AND INSTALL FRONT HOOD.

REMOVE AND INSTALL FRONT SPLASH GUARD—IF EQUIPPED.

REMOVE AND INSTALL REAR BODY COWLING.

Wheels and Bearings.

REMOVE AND INSTALL FRONT WHEEL.

INSPECT AND REPLACE FRONT WHEEL BEARINGS.

REMOVE AND INSTALL REAR WHEELS.

Rake Assembly.

REMOVE AND INSTALL RAKE.

INSPECT AND REPAIR RAKE.

INSPECT AND REPAIR MANUAL RAKE LIFT LEVER AND LINKAGE ASSEMBLY.

INSPECT AND REPAIR HYDRAULIC RAKE LIFT LINKAGE ASSEMBLY.

40 Inch Front Blade Assembly.

REMOVE FRONT BLADE.

INSTALL FRONT BLADE.

INSPECT AND REPAIR FRONT BLADE.

Cultivator Assembly.

REMOVE AND INSTALL CULTIVATOR.

INSPECT AND REPAIR CULTIVATOR.

INSPECT AND REPAIR CULTIVATOR LIFT LEVER AND LINKAGE.

SECTION 210 TEST & ADJUSTMENT SPECIFICATIONS.PROCEDURES.

Test & Adjustment Specifications.

TEST AND ADJUSTMENT SPECIFICATIONS.

Operational Checkout Procedures.

OPERATIONAL CHECKOUT PROCEDURES.

ENGINE OIL LEVEL AND CONDITION CHECK.

WET REDUCTION CLUTCH OIL LEVEL AND CONDITION CHECK.

OPTIONAL FRONT LIGHT TEST.

NEUTRAL—START TEST.

ENGINE START TEST.

ENGINE FAST AND SLOW IDLE TEST.

TRANSAXLE FORWARD.TEST.

DRIVE ENGAGEMENT AND SHIFT TEST.

BRAKE.TEST.

DIFFERENTIAL LOCK TEST.

STEERING TEST.

SECTION 220 ENGINE OPERATION, TESTS & ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

ENGINE INTERNAL COMPONENTS.

ENGINE LUBRICATION SYSTEM COMPONENTS.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

LUBRICATION SYSTEM OPERATION.

BREATHER SYSTEM OPERATION.

COOLING SYSTEM OPERATION.

GOVERNOR OPERATION.

AUTOMATIC COMPRESSION RELEASE OPERATION.

Diagnosis, Tests & Adjustments.

DIAGNOSTIC INFORMATION.

ENGINE CRANKS BUT WILL NOT START OR STARTS HARD.

ENGINE WILL NOT STAY RUNNING OR RUNS ROUGH.

ENGINE SPINS SLOW OR KICKS BACK.

ENGINE HAS BLACK SMOKE AT START OR DURING OPERATION.

ENGINE HAS BLUE SMOKE AT START OR DURING OPERATION.

ENGINE USES TOO MUCH OIL.

ENGINE SURGES.

ENGINE HAS UNEVEN OR UNCONTROLLED RPM.

ENGINE HAS LOW POWER.

ENGINE HAS LOW POWER—CONTINUED.

ENGINE FLOODING.

ENGINE STOPS WHEN HOT.

ENGINE BACKFIRES THROUGH CARBURETOR.

ENGINE BACKFIRES AT SHUT-DOWN.

ACCELERATOR CABLE ADJUSTMENT.

CHOKE ADJUSTMENT.

GOVERNOR ADJUSTMENT.

FAST IDLE SPEED ADJUSTMENT.

SLOW IDLE SPEED ADJUSTMENT.

COMPRESSION AND CYLINDER LEAKAGE TEST.

VALVE CLEARANCE ADJUSTMENT.

COMPRESSION RELEASE CHECK.

CRANKCASE VACUUM TEST.

FUEL PUMP TESTS.

SECTION 230 FUEL.ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

ENGINE FUEL AND AIR COMPONENTS.

FUEL SYSTEM COMPONENTS.

CARBURETOR COMPONENTS.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

FUEL SYSTEM OPERATION.

CARBURETOR FLOAT AND MAIN CIRCUITS OPERATION.

SLOW AND FAST IDLE CIRCUITS OPERATION (NO LOAD).

CARBURETOR CHOKE CIRCUIT OPERATION.

FUEL PUMP OPERATION.

Diagnosis, Tests & Adjustments.

DIAGNOSTIC INFORMATION.

FUEL.ADJUSTMENTS.

SECTION 240 ELECTRICAL OPERATION, TESTS & ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

1200 BUNKER RAKE ELECTRICAL COMPONENT LOCATION.

FE290 ENGINE ELECTRICAL COMPONENT LOCATION.

HYDRAULIC LIFT AND FRONT LIGHT COMPONENT LOCATION.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

WIRE COLOR CHART.

CRANKING SYSTEM OPERATION.

IGNITION SYSTEM OPERATION—ENGINE RUNNING.

IGNITION SYSTEM OPERATION—ENGINE SHUTTING OFF.

CHARGING SYSTEM OPERATION.

OPTIONAL FRONT LIGHT SYSTEM OPERATION.

HOURMETER.OPERATION.

OPTIONAL ELECTRIC-HYDRAULIC LIFT SYSTEM OPERATION—LIFT.

OPTIONAL ELECTRIC-HYDRAULIC LIFT SYSTEM OPERATION—LOWER.

Diagnosis, Tests & Adjustments.

DIAGNOSTIC INFORMATION.

CRANKING CIRCUIT TEST POINTS.

IGNITION CIRCUIT TEST POINTS.

CHARGE SYSTEM TEST POINTS.

FRONT LIGHT CIRCUIT TEST POINTS.

HOURMETER.POINTS.

ELECTRIC-HYDRAULIC LIFT CIRCUIT TEST POINTS.

ELECTRIC-HYDRAULIC LOWER CIRCUIT TEST POINTS.

BATTERY VOLTAGE & SPECIFIC GRAVITY TESTS.

CHARGE BATTERY.

LOAD TEST BATTERY.

REGULATED VOLTAGE TEST.

STATOR UNREGULATED OUTPUT TEST.

AMPERAGE OUTPUT TEST.

STARTER SOLENOID TEST.

STARTER LOADED AMPERAGE AND RPM TESTS.

STARTER NO-LOAD AMPERAGE TEST.

ADJUST IGNITION COIL AIR GAP.

IGNITION COIL TEST.

IGNITION MODULE TEST.

SPARK PLUG GAP ADJUSTMENT.

KEY SWITCH TEST.

FLYWHEEL MAGNET TEST.

TRANSAXLE NEUTRAL SWITCH TEST.

OPTIONAL HYDRAULIC LIFT.TEST.

OPTIONAL FRONT LIGHT SWITCH TEST.

GROUND CIRCUIT TEST.

Wiring Schematics.

SCHEMATICS INFORMATION.

LEGEND FOR 1200 BUNKER RAKE ELECTRICAL SCHEMATIC.

SECTION 250 POWER TRAIN OPERATION, TESTS & ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

POWER TRAIN COMPONENTS.

WET REDUCTION CLUTCH COMPONENTS.

TRANSAXLE COMPONENTS.

DRIVE CLUTCH COMPONENTS.

DRIVEN CLUTCH COMPONENTS.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

WET REDUCTION CLUTCH OPERATION.

DRIVE CLUTCH OPERATION.

DRIVEN CLUTCH OPERATION.

DRIVEN CLUTCH OPERATION—CONTINUED.

DRIVEN CLUTCH OPERATION—CONTINUED.

DRIVEN CLUTCH OPERATION—CONTINUED.

DRIVEN CLUTCH OPERATION—CONTINUED.

CLUTCH SYSTEM OPERATION.

TRANSAXLE FORWARD OPERATION.

TRANSAXLE REVERSE OPERATION.

DIFFERENTIAL LOCK OPERATION.

Diagnosis, Tests & Adjustments.

DIAGNOSTIC INFORMATION.

LACK OF DRIVE—ONE DIRECTION.

LACK OF DRIVE—BOTH DIRECTIONS.

NOISY OPERATION—ONE OR BOTH DIRECTIONS.

VEHICLE CREEPS—IN GEAR AT IDLE.

JERKY OR AGGRESSIVE ENGAGEMENT.

SLOW ERRATIC ACCELERATION.

PREMATURE BELT WEAR.

DIFFERENTIAL LOCK WILL NOT OPERATE.

DRIVE BELT INSPECTION.

TRANSAXLE SHIFT CABLES ADJUSTMENT.

FULL UPSHIFT CHECK.

DRIVEN CLUTCH SPRING TORSION CHECK.

DRIVEN CLUTCH SPRING TORSION ADJUSTMENT.

SECTION 260 STEERING & BRAKES OPERATION, TESTS & ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

STEERING COMPONENTS.

BRAKE COMPONENTS.

BRAKE CALIPER COMPONENTS.

BRAKE PEDAL COMPONENTS.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

STEERING SYSTEM OPERATION.

BRAKE OPERATION.

Diagnosis, Tests & Adjustments.

DIAGNOSTIC INFORMATION.

STEERING VIBRATION OR NOISE.

BRAKE EFFORT, NOISE, WEAR OR ADJUSTMENT.

BRAKE CABLE ADJUSTMENT.

SECTION 270 HYDRAULIC SYSTEM OPERATION, TESTS & ADJUSTMENTS.

Component Location.

COMPONENT LOCATION INFORMATION.

HYDRAULIC LIFT SYSTEM COMPONENTS.

HYDRAULIC LIFT PUMP COMPONENTS.

Theory of Operation.

THEORY OF OPERATION INFORMATION.

HYDRAULIC LIFT SYSTEM OPERATION.

HYDRAULIC LIFT SYSTEM OPERATION—CONTINUED.

HYDRAULIC LIFT SYSTEM OPERATION—CONTINUED.

HYDRAULIC LIFT SYSTEM OPERATION—CONTINUED.

Diagnosis, Tests & Adjustments.

DIAGNOSTIC INFORMATION.

LIFT CYLINDER WILL NOT RAISE.

LIFT CYLINDER WILL NOT LOWER.

RAISE RELIEF VALVE PRESSURE TEST.

LOWER RELIEF VALVE PRESSURE TEST.

Hydraulic Schematic.

INDEX.

Reviews

There are no reviews yet.